At TSI, we are a team of experienced engineers dedicated to developing innovative products using the latest technology in food dehydration. We understand the importance of preserving food in its natural state while still maintaining its nutritional value, which is why we have created a dehydrating machine that is not only efficient but also easy to use.

With years of expertise in the industry, we have continuously strived to improve our products and provide our customers with the best possible solutions for dehydrating cooked food. Our machines are designed to remove moisture from food while retaining its flavor and nutrients, ensuring that you can enjoy delicious, healthy snacks and meals without compromising on quality.

We are committed to customer satisfaction and are always looking for ways to enhance our products and improve our service. Whether you are a home cook looking to preserve seasonal produce or a professional chef seeking to add dehydrated ingredients to your menu, TSI has the solution for you.

Trust in our team of engineers to deliver reliable, high-quality dehydrating machines that will revolutionize the way you store and enjoy cooked food. Join us on our mission to make food preservation easy, efficient, and delicious.

At TSI, we specialize in manufacturing high-quality cooked food dehydrating machines that are perfect for businesses in the food industry. Our machines are designed to efficiently and effectively dehydrate cooked food items, preserving their natural flavors and nutrients while extending their shelf life.

Our team of experienced engineers and designers work tirelessly to create machines that are reliable, easy to use, and built to last. We understand the demands of the food industry and strive to meet and exceed our customers’ expectations.

When you choose a cooked food dehydrating machine from TSI, you can trust that you are getting a top-of-the-line product that will streamline your food processing operations and improve your overall efficiency. Whether you are dehydrating fruits, vegetables, meals, or grains, our machines are up to the task.

Additionally, we offer excellent customer service and support to ensure that you are fully satisfied with your purchase. We are committed to helping our customers succeed in their businesses and are always available to assist with any questions or concerns that may arise. Choose TSI for all your cooked food dehydrating machine needs and experience the difference that quality and reliability can make in your food processing operations. Contact us today to learn more about our products and how they can benefit your business.

A cooked food dehydrating machine is a device used to remove moisture from cooked food, preserving it for longer periods of time. This machine works by circulating hot air around the food, evaporating the water content and leaving behind a dried product. This process helps to inhibit the growth of mold and bacteria, extending the shelf life of the food. Cooked food dehydrating machines are commonly used for making snacks like dried fruits, vegetables, as well as for preserving meals for camping or traveling to places where home food is not available.

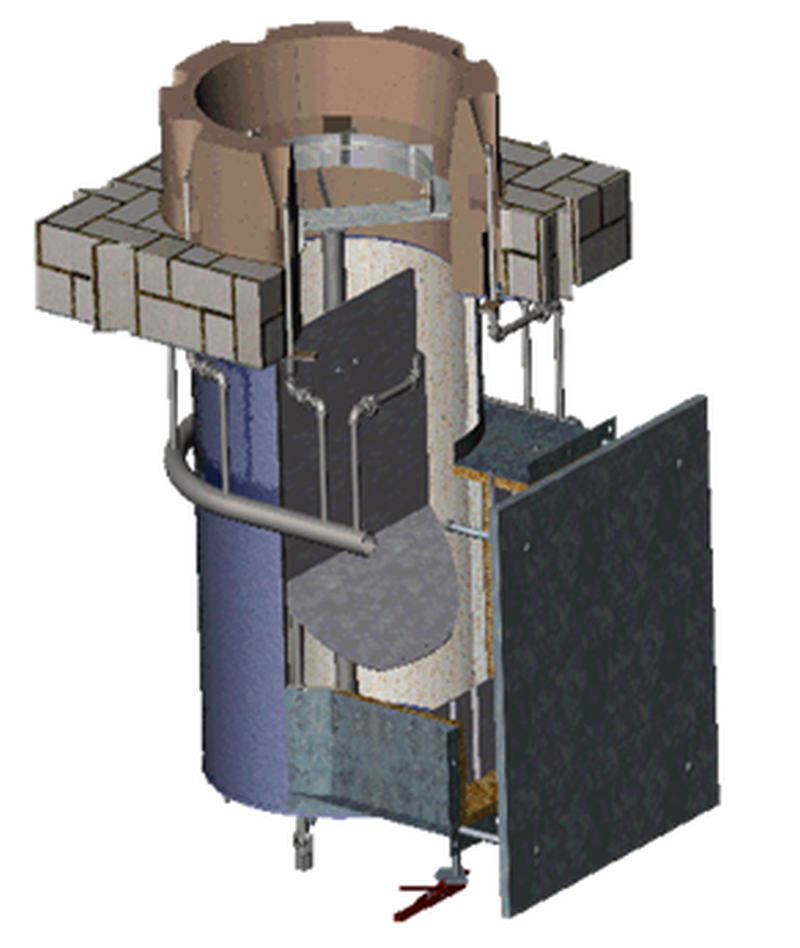

An experimental tray dryer for cooked food dehydration has been developed by TSI. This state-of-the-art tray dryer is designed to help us conduct experiments and tests on various products to optimize their drying process.

The tray dryer features multiple trays where products can be placed and dried simultaneously. It also includes temperature and humidity controls, allowing us to adjust the drying conditions according to the specific requirements of each product.

With this experimental tray dryer, we can closely monitor the drying process and make real-time adjustments to ensure optimal results. This allows us to speed up the product development process and make improvements more efficiently.

The tray dryer consists of several shelves or trays stacked one on top of the other within a chamber. The trays are typically made of stainless steel to withstand the high temperatures used in the dehydration process. The chamber is equipped with a heating element and a fan to evenly distribute heat and air throughout the trays.

In operation, the cooked food is spread out in a thin layer on the trays so that the hot air can effectively remove moisture from all surfaces. The temperature and airflow can be adjusted to suit the specific requirements of each food product being dehydrated.

The experimental nature of this tray dryer allows for testing and optimization of different parameters such as temperature, airflow, and drying time to achieve the best results for different types of cooked food. By conducting experiments with various settings, we can determine the most effective dehydration conditions for specific food products.

Additionally, the tray dryer can be used to study the effect of dehydration on the sensory qualities and nutritional content of the cooked food. We can analyze changes in flavor, texture, color, and nutrient levels before and after dehydration to determine the impact of the drying process on the overall quality of the food.

By conducting controlled experiments with this device, we can better understand the dehydration process and develop optimized drying techniques for a wide range of food products.

A food dehydrating machine is a device used to remove moisture from food items, preserving them for longer periods without refrigeration. This process is known as dehydration and helps prevent the growth of bacteria, yeast, and mold.

Process Burners are very crucial for efficient combustion and heat transfer in furnace and fired heaters: TSI has deep understanding and practical experience of process burners. The design of burners is very important for efficient mixing of fuel and combustion air.

Cold plates are very critical as they need to take out lot of heat within a confined space and maintain lower surface temperatures in many critical electronic equipment’s. It is very challenging to design the flow path which ensure effective heat removal and keeping the surface temperature within the limits.

T Solutions India designs the most efficient pathway for cooling fluid so that the heat transfer efficiency is very high, meeting the stringent criteria of space and achieving lower surface temperatures.

TSI is working on the next level upgrades to virtually validating the cold plate efficiency on PCB gerber data and on-board electronics.

T Solutions India has vast industrial experience for many applications related to Food Drying, Process, Oil & Gas and others. TSI focus is always towards developing the basic working philosophy of any equipment. Based on that design products that are highly efficient to deliver a high-quality output at the same time reducing its impact on Environment.

Office No. 6

Vrundavan Commercial Complex, 2nd Floor

Above Ujjivan Small Finance Bank D.P.Road, Kothrud

Pune 411038

Phone: +91 98232 55352

E-mail:achilka@tsolutionsindia.com

WhatsApp us